Sharing her conviction that a fully integrated approach is key, Ms Claudia de Witte, Sustainability Leader, Textiles at Eastman Chemical Company, said: “It is extremely important to be transparent and third-party certified, and to do it holistically. Industry trends and focus points have shifted over the past few years, and evolved at different speeds in different regions. More recently however, from a legislative perspective and industry consortium perspective, everybody is starting to embrace this holistic thinking, because you cannot only focus on one element of sustainability.”

Discussing the evolving nature of global policy and the challenges that have arisen, Mr Marc Sidler, Group CMO of TESTEX AG, commented: “OEKO-TEX® has always prided itself on going beyond legal requirements, and when we started more than 30 years ago, there were no regulations. Today there are many around the globe, and we strive to find worldwide certification solutions for our customers along the entire supply chain.”

“Traceability is growing ever more essential for the industry, and it’s a must for downstream manufacturers to know where their materials are coming from,” said Ms Tina Lee, Marketing Director of Huafu Top Dyed Melange Yarn, in her opening remark on transparency. “We started setting up a transparent system a long time ago, and we can provide our buyers with the country of origin for every bale of cotton, polyester fibre, or even cellulose fibre, and our production system can trace our readymade yarn to the fibre sourcing crop.”

A global change in perspective – the economy’s shift towards sustainability and social responsibility

The world has come a long way when it comes to bettering environmental and social practices, although there is still much multi-sector progress to be made before the goal of carbon neutrality, or net zero, can be met by 2050. The textile industry has been cited as one that needs to make faster progress.

Transparency has always been instrumental in the way we do business at Naia™ from Eastman, and we are really excited that this is now an industry trend and being adopted in policy development, because this will push the textile industry to the healthier place it needs to be,” said Ms de Witte. “I hope that the industry’s enhanced transparency, understanding, and raising consumer awareness about the actual garment’s global journey, will also mean enhanced accountability for all the players along the value chain.”

When prompted to give examples of changing worldwide policy, Mr Sidler proffered: “We are focusing on aligning OEKO-TEX® RESPONSIBLE BUSINESS with the German Supply Chain Act, as it is a law which is already in place. Another proposal is the EU Strategy for Sustainable and Circular Textiles. In addition, others we have looked into include France’s Duty of Vigilance Law, the UK’s Modern Slavery Act, and the Dutch Child Labour Due Diligence Law.” He added: “The pressure on companies to be more sustainable and socially responsible comes from two places – firstly, from end consumers, especially younger generations, and also from governments and regulators to protect the end consumer.”

Expanding on social responsibility, Ms Nicole Soliani, Group Communication Officer of TESTEX AG, said: “You have probably often heard the question ‘Who made my clothes?’, which is coming from the consumer side – that has pushed all the certifiers to look more at social responsibility. Thus it's not only about ‘Are my clothes safe? Am I protecting the environment?’ It's about asking if the person making the clothes is being paid enough, and if they are working in safe conditions. That's where STeP comes in.”

“It is not only European or US buyers requesting downstream transparency. It is a cornerstone for us to maintain our business, as opposed to using it to grow significantly. Without such a system, continued operation is not possible,” commented Huafu’s Ms Lee. “I also think it’s a necessary responsibility for suppliers to make their supply chains transparent so that customers can set their minds at ease with the knowledge that fibre resources are sustainable and compliant.”

How can key industry players adapt to this shift without greenwashing?

Consumers are cottoning on to the need for eco-friendly clothing, and many innovations are now aimed in this direction. However, one accusation levelled at the global textile industry has been that companies are greenwashing their products and brands, in efforts to make them appear more sustainable than they are in reality.

In order to ensure globally aligned standards to prevent greenwashing, Mr Sidler noted three necessary considerations: “Number one, independent labels such as OEKO-TEX®, which are important for safeguarding credibility. Secondly, alignment in terms of manufacturing standards and limit values, between us and organisations such as ZDHC, Leather Working Group, and Textile Exchange to provide joint solutions so that the supply chain is not confused by different rules. Thirdly, brands need to be transparent about their supply chains and we have seen that the percentage of brands disclosing this information has increased dramatically in the past few years.”

Ms Lee stressed the importance of environmentally friendly raw materials, commenting: “For the product development side, sustainable material use is more important than production processes – such as new fibre development, and how these are integrated into yarns and fabrics. Most of our customers are requesting the switch to eco-friendly fibre alternatives, such as more sustainable cotton or recycled and biodegradable polyester.”

Ms de Witte maintained that third-party verification and transparency along the entire supply chain are necessary to ensure greater sustainability, explaining: “There are a large number of certifications that target different stages of the process, and taking a holistic approach is very

important, because you cannot focus on a sustainable sourcing story if you are using hazardous chemicals. At Naia™, we focus on all of the brackets – sustainably sourced wood pulp, which is FSC® and PEFC™ Chain-of-Custody certified; closed-loop, non-hazardous manufacturing, and we have an OEKO-TEX® Product class 1 certification; 40% recycled waste materials for Naia™ Renew, being verified by ISCC; biodegradability, audited by TÜV AUSTRIA; as well as environmental impact, for which we are ISO-compliant and publicly scored on Higg.”

Collaboration and a well-rounded approach needed to propel the textile industry towards circularity

Striving towards sustainability is a truly global effort, and requires key industry players along and adjacent to the supply chain to work together to innovate, verify, and educate.

Ms de Witte said: “One example is our recent digital traceability partnership with TextileGenesis™, which is a blockchain-enabled supply chain traceability platform for the textile industry, and it helps us achieve our sustainability goals. They are partnering with some leading brands, and by also having sustainable fibre producers on this platform, we can really initiate that exciting track and trace solution.” She continued: “Education is needed at consumer and brand level, but we have also worked hard to educate the future sustainability minded designers. Such as at the Fashion Institute of Technology in New York, where we are teaching and inspiring young generations about the use of sustainable fibres. We also sponsored the exciting RISE UP Sustainable Fashion Design Challenge in 2021 and 2022 in Shanghai, where competitors from all over the world used Naia™ yarns and fibres to create complete collections.”

Ms Lee spoke towards multifaceted, sustainable innovation, commenting: “We specialise in producing top-down mélange yarn, which is itself a very sustainable process. We dye a percentage of our fibre before blanching and spinning, which can save at least 50% water consumption. Additionally, we utilise a lot of sustainable fibres, such as Better Cotton Initiative and Global Recycle Standard cotton, GRS-certified recycled polyester, and dupe dye polyester. We also have a new biodegradable polyester – the uptake is not yet very high, but it is growing. Clean energy is also very important, and about 30% of our Vietnam factory’s electricity demands are met by rooftop solar power.”

Ms Soliani noted the need for industry wide certification, but also stated that businesses need to be responsible for the compliance of their own suppliers and partners: “RESPONSIBLE BUSINESS covers the whole supply chain, and aims to ensure that input, process, and output are properly certified in regards to human rights and environmental criteria. Businesses need to evaluate their own supply chains and answer the question ‘Are we being socially responsible?’ They need to ensure that all the links in their supply chains conform to due diligence requirements.”

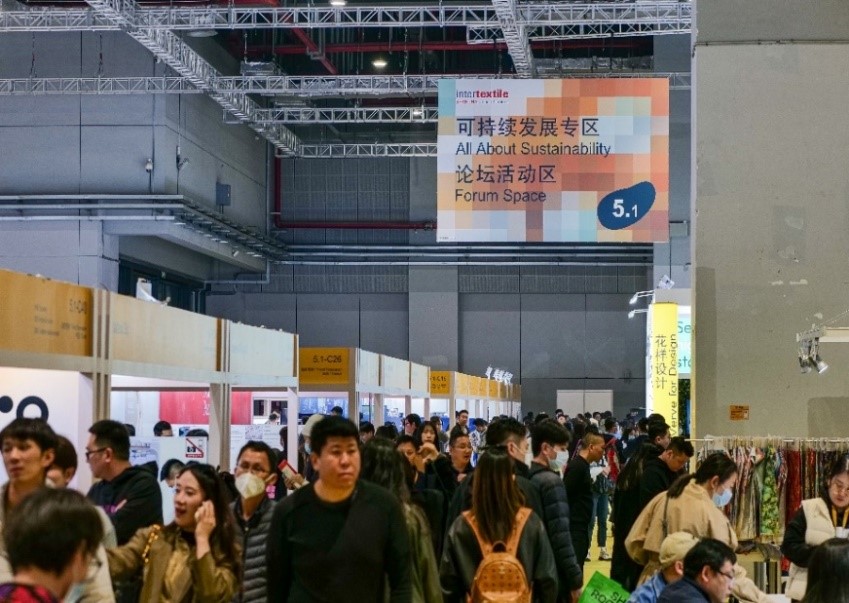

Alongside much of the international textile industry, Eastman, Huafu, and TESTEX exhibited at this year’s Intertextile Shanghai Apparel Fabrics – Spring Edition. The fair took place from 28 – 30 March 2023 at the National Exhibition and Convention Center (Shanghai), and was held concurrently with Intertextile Shanghai Home Textiles – Spring Edition, Yarn Expo Spring, CHIC, and PH Value.

The fair is co-organised by Messe Frankfurt (HK) Ltd; the Sub-Council of Textile Industry, CCPIT and the China Textile Information Centre.

For more details on this fair, please visit: www.intertextileapparel.com. Information regarding the international textile sector and Messe Frankfurt’s textile fairs worldwide can be found at: www.texpertise-network.com.

Media Contact:

Flora To

flora.to@hongkong.messefrankfurt.com

Tel: +852 2230 9226

Sales Contact:

Jimmy Chan

Jimmy.chan@hongkong.messefrankfurt.com

Tel: +852 2238 9999